We just posted what might be our most extreme testing video yet, and no surprise, we didn’t hold back. If you haven’t seen it yet, click here to check it out! (video releases 7/19/25)

We dragged the Fireball 510 Hardtail Vise behind a truck,

Twisted pipe in it, pushed it with hydraulic cylinders,

And compared it head-to-head with two legends:

- The Reed 205 – A vintage vise that sat on service trucks back in the 1920s. A symbol of “they don’t make them like they used to” engineering

- The Snap-On 1765 – A modern day favorite, based on the classic Wilton design

We did this to find out what it really takes to break a vise.

We weren’t interested in specs or reputation. We wanted survivability and what happens when a vise is pushed beyond what it was designed for.

So here’s a full breakdown of the gauntlet, and how each vise performed.

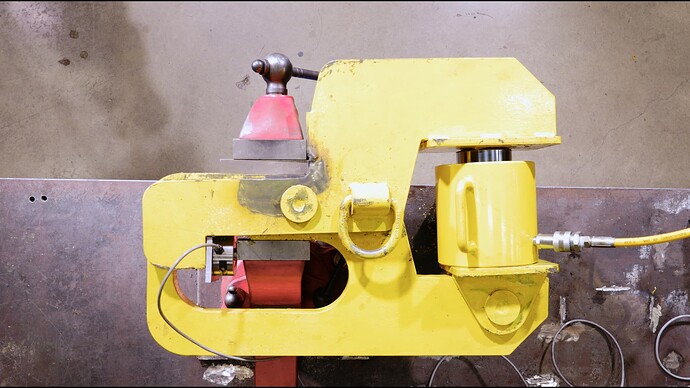

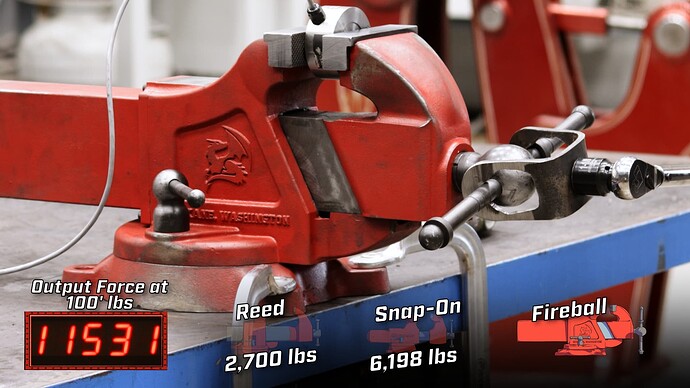

Clamping Force Test

We used a torque wrench to apply 100 ft-lbs to each vise and measured how much clamping force that produced.

Results:

- Reed 205 – 2,700 lbs

- Snap-On 1765 – 6,200 lbs

- Fireball 510 – 11,531 lbs

The 510 turns torque into clamping force like a monster. You don’t need a cheater bar just tighten the handle by hand and it grabs.

Pipe Twist & Lift

To simulate real-world pipe work, we clamped a piece of tubing and used a long lever to twist and lift it out of the jaws — like trying to unstick a rusted pipe fitting in the field.

This test was also done at two distances from the lever, 28 inches and 6 inches. Here’s what we found:

Reed 205

- 28 inches: – 607 bs

- 6 inches – 983 lbs

Snap-On 1765

- 28 inches: – 651 lbs

- 6 inches – 877 lbs

For this test, the handles on the Reed 205 and Snap-On 1765 were twisted until they were bent, ensuring maximum clamping force was being used.

Now we come to The Fireball 510 Hardtail. We gave this vise a huge disadvantage by only tightening with hand strength. No cheater bars, no bent handles. The jaws can also be interchanged with 3 different types:

Stock, Soft, and Pipe-V Jaws. So we tested all three:

Fireball 510

- Stock jaws

- 28 inches – 530 lbs

- 6 inches – 990 lbs

- Soft aluminum jaws

- 28 inches – 380 lbs

- 6 inches – 750 lbs

- V-pipe jaws

- 28 inches – 2,340 lbs

- 6 inches – 2,623 lbs

The Fireball’s V-pipe jaws grip harder than anything else tested. And our soft jaws let you hold without damaging finished work.

Swivel Base Strength Test

Next, we locked each vise’s swivel base and applied torque 28 inches out from center using a hydraulic ram. Once again, the handles on the Snap-On and Reed were twisted until they were bent, applying the most force they could handle.

Results:

- Reed – Slipped at 668 lbs

- Snap-On – Base broke at 694 lbs. Inside the base, the locking teeth were flattened and the handle spindles were bent and twisted

- Fireball 510 – Held strong at 1,886 lbs with zero damage

The 510’s wedge-style locking system flat-out works. It’s stable under real pressure, without bending or skating like the others.

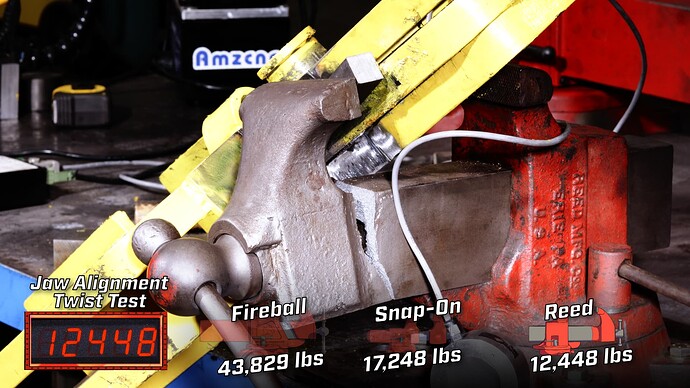

Jaw Alignment Twist Test

And now we arrive at our final test, intended to break each of the vises until they were unusable. We clamped a custom steel frame and forced it sideways using tons of hydraulic pressure the goal was to simulate real field abuse and see what breaks first. We switched up the order and tested The Fireball 510 Hardtail first. This way, we could set a benchmark, and if the other vises could pass The 510’s limit, we would spare them.

Results:

- Fireball 510 – Survived 43,829 lbs before shearing one bolt

- Casting remained intact

- Snap-On – Failed at ~17,248 lbs, with the dynamic jaw fully bent to the floor, and twisted out of alignment

- Reed 205 – Shattered at ~12, 448 lbs, cast iron exploded on the dynamic jaw

The 510 absorbed more than double the load of either competitor and kept going. Neither the Reed nor the Snap-On made it past 20,000 lbs without becoming scrap.

After all that, we pulled the vises apart. Some were fixable. Others were just plain toast.

But the 510 took everything we threw at it including being dragged behind a truck at speed before testing and still outperformed every other vise in the lineup.

The Best Vise Ever Made

We designed The Fireball 510 Hardtail Vise to be a field-ready, high quality service truck vise, and after these tests, we truly believe its the Best Vise Ever Made.

But we want the world to know that too. So were asking you, The Fireball Tool Community, to help us spread the word. Post your experiences with the 510 right here under this post or make your own post. Talk about why you like the 510 on reddit, or anywhere else on the internet.

And if you like this video and want to see more:

- Drop your test ideas here in the forum. We actually read them and use them to shape the next videos.

- Want us to try rebuilding the broken vises? Let us know! We’re game if you are.

We’re not trying to make the cheapest vise.

We’re trying to make the last one you’ll ever need to buy.

Let us know what you think. And if you’re one of those folks who says “I don’t trust a vise until it’s broken a bolt or two,” well, we’ve got footage of that too.

And click here to get yourself a Fireball 510 Hardtail Vise or click here for its older brother The 614 Hardtail.

See you in the next test