I’m a small time fabricator in my 50’s. I’ve been making signs and the occasional table or something with my CNC plasma cutter for about 15 years, but I’ve been just ITCHING to get a fixture table ever since I started watching Jason’s videos on YouTube. Now I’m pretty broke these days so I can’t afford something like a Fireball table but I really enjoy working with metal so I do what I can. About 12 years ago I was gifted a 4x6 sheet of 1" steel plate so I made a welding table. It had a pretty big bow in the middle, but I made do with it for all these years. Clamping to the edge of the table like a caveman… Here’s a pic of what it “used” to look like.

I found a friend with a laser cutter that said if I paid for the steel, and traded him some old Willys jeep parts, he’d cut me some holes in it for me. He said he could cut 1/2" steel with his laser. I like my 1" top, but I’ve really never had a time where I thought, “Golly, I’m glad my top is 1” thick!" so I took him up on his offer and had him cut a 48"x 72" sheet of 1/2" thick steel with 805 5/8" holes set on a 2" grid pattern. After about a week, he told me it was done. I pulled off the 1" thick top to make room for the new sheet.

Using a skid steer with forks, the new top was on in a jiffy!

I have actually lost sleep over this next part… I really wanted to use Fireball fixtures. I love the tooth block design and the 2 pin design of the fence blocks, but was literally terrified that the fence blocks weren’t going to fit. I had heard Jason mention once that spacing should be in the +/-.002 range and my laser guy says his table has a tolerance of about +/-.005 so I was very worried that I was going to have a table that would have great clamping abilities, but not be able to use the Fireball fence blocks (Well, with two pins at least) I also really like his larger fence blocks and the ability to use them in a 45 degree setup but again… terrified they wouldn’t work.

So first test… do I really have a 2" grid pattern…?

Yes! they fit great!

Next test, can I use the FBT long fence blocks on a 45 degree…?

Yes! They fit great also! I guess lasers do actually work!

I’m assuming these are going to be my bread and butter fixtures for the stuff I’ll be making.

Now for flatness. With my old 1" top, it had about a 1/4" gap over the 6’ span. I didn’t like it, but I made it work. Honestly, if I could make this ANY better than that, I’d be happy. I set my 6’ level on the 4’ side. It was flat. Now I didn’t get out the feeler gauges, but the level didn’t wobble anything noticeable so I was very happy with that.

Over the 6’ length, things were different. There was almost an 1/8" of wobble on the level. Many years ago, I tried to pull my old 1" sheet with clamps and bolts, but it wouldn’t budge.

Now, I was hoping I could pull this 1/2" sheet into place if I needed to, so I tried putting a clamp underneath and was able to pull it perfectly into place! Again… I didn’t get out the feeler gauges, but if my 6’ level looks good, I’m happy! I’ll weld on a nut or something to make it more permanent.

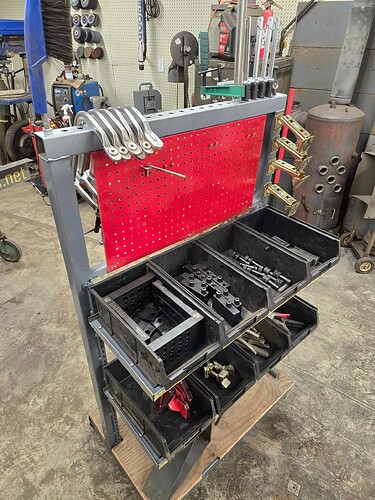

I also made a rolling cart for my fixtures and clamps. I looked at a bunch of different designs for storage and really liked the design Jason had, so I based it on his design. I don’t have too many fixtures yet, but I hope to change that in the future.