I’m working with 2x2x.083 square tubing. I’ve come to the conclusion that even though I can get “better” results by knocking .125" off of my desired dimension and cutting to that line, I need to be able to trim to length in order to get repeatable results. That brings up my next question. Would a consumer-grade 1hp. 12" disc grinder with a mitering fence in the $3-500 range with an appropriate abrasive be adequate for the purpose of taking a few 16ths at most off and squaring up the ends? I couldn’t help but notice that even a top-tier fabricator needed to touch up a couple of parts to get the fitup he was looking for in the excellent live-stream of the table-test build.

Yes, I understand the utility of a wide-base combo square for spanning the radius to make the mark illustrated in the photo. It’s marking the 45 in order to cut to length at the point where the square is resting on the top of the piece that I’m struggling with. I can do that with math for round stock as has been pointed out elsewhere in the thread; it’s the small radius on the corners of square tubing that’s kicking my butt.

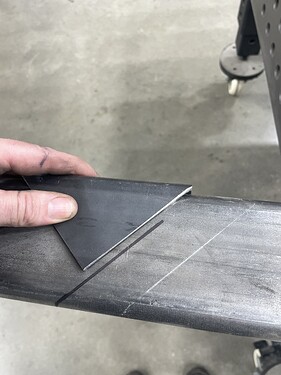

So like this… excuse the crappy line, its only like 30 degress in the shop still and hands would like much warmer lol

Line up the vertical face of the square on the vertical line. If you notice, the outside edge of the ruler is flush with the body. The 45 along the edge of the ruler will intersect with the vertical face.

IoW - in Dan’s photo if the square was lined up on the front face with the vertical line - about 2 or 3" towards the mark on the tubing - the ruler will intersect the mark on the top “out in space” at the correct place. Does that make sense?

also, are you referring to an abrasive chop saw? They should be sufficient - though an evolution/metal chop saw will give you much nicer cuts - though they fling hot metal chips all over. But that’s probably better than grinding dust (and the part stays cooler)

Ketmorco, thats what I was hoping to get across . Now if Im laying out a bunch of the same angle thats not a 45. Ill just take a scrap piece of angle iron, or a next larger size tube and cut in half length wise…cut my angle on that, and El Cheapo insta square

Maybe you know already, but here goes.

Assuming you have a 2x2 square tube with the radiused corners and cut perpendicular on the end in question and you want to cut a certain length with a 30 degree angle.

Draw a line down the center of the tube. I use a vernier calliper. In this case 1”. Then using tangent of 30 degrees with opposite side being 1 , you calculate the adjacent length (1/.577=1.732 in this case). Subtract this from the overall measurement, measure and center punch a mark on the centreline you created. Have your saw set for the appropriate angle (30 in this case) and cut on the correct side of the center punch mark for the keeper piece of material.

Of course use the correct tangent value for whatever degree of cut you want to achieve.

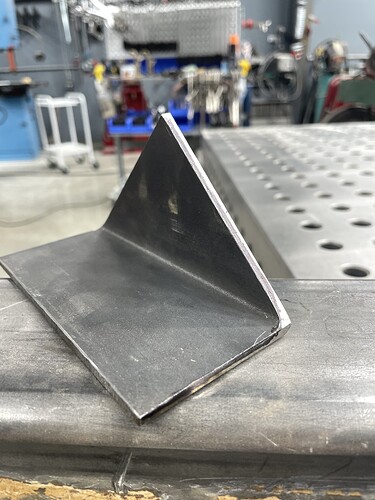

Make yourself one of these. It’s a section of tubing. They can be very handy for a speedy layout. You can make a 22.5 or 60 degree versions. Sometimes a speed square is to large and needs to be reset after the 45.

Yes Jason, thats what I was talking about yesterday! Super handy, even when it becomes a sacrificial gusset by accident sometimes lol.

Inconvenience Store

Credit to Gary Larson

The only issue I see is that your template is cut normal to the surfaces rather than a full 45° miter cut like he would need it laying out off of the theoretical sharp point, but that’s should be easy enough to remedy by leaving it a sharp angle cut.

@mRhAnKbOt It’s the inside of the template that’s important. The sharp edge doesn’t do anything but get in the way. Grind it off so you can mark easier.

I’m going to use this idea tomorrow

Thanks

I used the fireball combo square it works for 45

I use adjustable square too for other angles

Edited because I realized it’s all about lining the diagonal edge up with the inside edge of the tip of the 45 angle on the scribing jig and it’ll still make a 45° (or whatever). Not sure why I was thinking you need to have the sharp corner. Up too late cutting parts for my new welding cart I guess. Maybe I’ll aim for more sleep tonight. ![]()

That’s a great idea, thanks.

I built a prototype base for my dry cut saw so I could use my fixtures and I get perfect miters every time now. Here’s the model of the saw and the fit up:

Nice job Henry! Did you use the Fireball drilling jig?

–Larry

No, Fireball doesn’t have a 5/8" jig yet. Getting them lined up was such a pain by hand and eye and it took hours. However, my Fireball fence blocks actually drop into almost any combination of the holes with 3 holes in the lot being too far off.

I drilled the holes with an annular cutter in my mag drill so they’re maybe +.003/.000" or so.

The hardest part was getting them exactly perpendicular to the saw blade but I used some of the Fireball squares to get that lined up and it worked great.

Henry that’s as good as it gets, Nice work!