I rarely need angles other than 45°, but I did get to wondering how y’all like to do it. If I want to have a continuous bend in a corner I’ve just been keeping some of the Stronghand Tools fixtures with a hole and slot around and using those. That way I can pick a couple of different hole locations and get a series of angles. It’s definitely an okay solution to a lot of my needs, but I’m curious if anybody else has something slick they like to use?

Do you use Cad in your shop? I can give you some tips if you do.

Oh, yeah. I don’t have any CNC equipment to run it on so I don’t use it all the time, but I’m totally open to suggestions.

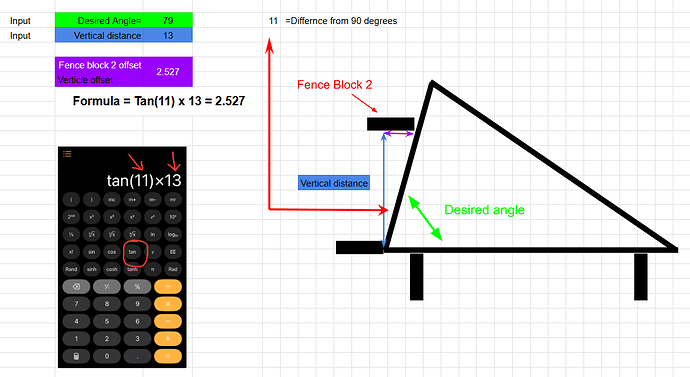

I’ll make a video on this topic. I’ll share more here when it’s done. Here’s a example of how to set angles. This is a guard rail post.

But the best way is use the grid of the table to accurately place a fixture in a position that sets the angle and distance. We make a fixture map that looks like this. The tooth blocks are really helpful for doing this. Each hole on the table gets labeled with a ABC, 123 designation. This method helps to remove errors from using a tape measure and using reference surfaces or layout lines.

This is a good idea. There are a few situations I’ve run into where you can’t do this but they’re pretty rare. I’m looking forward to the video.

Your videos sell more of your products than you know. When I showed my wife one of your videos using the fixtures on your table it convinced her how important it would be for us to have some Fireball fixtures for the projects I do around our house.

Seeing the table laid out with letters and numbers I have an overwhelming urge to play Battleship.

You should set up 4 tables for that and machine up some red and white pegs.

Making the battleships would be harder.

It would make an awesome video.

New video is up on the website

Yes this is a very accurate and repeatable way set the angle. This technique sets distance from an origin and angle. This should be standard practice with shims or the tooth block.

Getting the angle is easy. Now what’s the shim needed?

If fence block 2 is the new 5" adjustable fence block, I would set it to 2-1/2" (or 1/2" and move over one hole) and add 0.027" shim.

Or just go with 2-1/2" (close enough?? )

Pretty accurate… Good use of trigonometry.

Opposite = Tan (theta, the Complementary angle to the Desired Angle ) x the Adjacent side (the vertical side in blue).

Then with Fence block 2 being defined as the adjustable 5" version set at 2.5" leaves your closest shim in the pack 1/32" (.03125"), which is to long, by 0.0043059812". Plus any slop between the machined hole and pins.

This assumes the shim is placed on the lower corner of the fence block.

I use an online “right triangle calculator”.

That calculation will only work if the zero block is lined up to the bottom of the part.

Yes, the measurement has to be from the bottom of the part. (Because that’s where the angle is measured from) Good observation. The block is there just for illustrative purposes.