Can your speed square do this?

Today is a new tool birthday: the brand-new Fireball Miter squares.

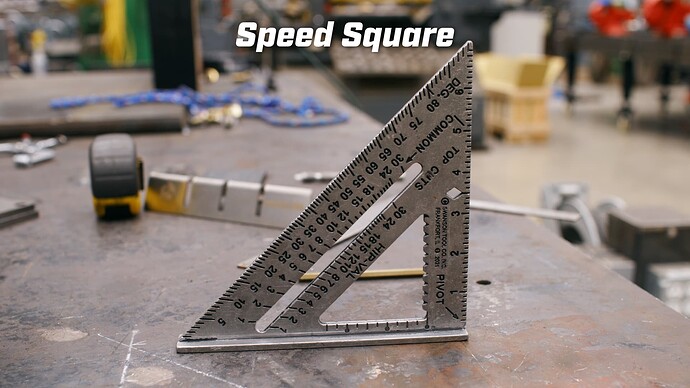

The speed square is one of our favorite tools in the workshop. Nothing’s ever going to replace it, but it has weaknesses. Same with the framing square, We love it, but it too has its limits. So we thought, what if we could combine some of those strengths while addressing the weaknesses? That’s how the Fireball Miter Square was born.

This tool isn’t here to take the place of your other squares, it’s simply another option that does something special. We call it the Fireball Miter Square for a reason: it was really designed for layout on tubing.

We’ve made them out of stainless steel to keep costs down, and they come in a 3-pack set for $32.

Fireball Miter Square vs Speed Square

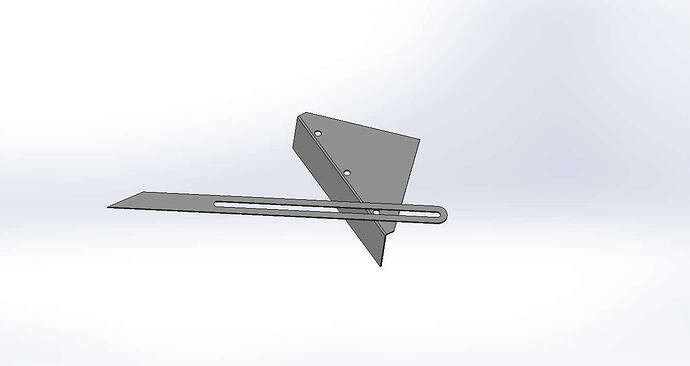

If you look at them side by side, the difference jumps out. The speed square’s hook is located on one of the 90° legs, leaving the hypotenuse open. On the Fireball Miter Square, the hook moves to the hypotenuse. It’s larger, and it’s only on one side. So in a sense, the Fireball Miter Square is like the speed square and framing square combined, with a long leg and a big hook.

In Use: Quick Layout

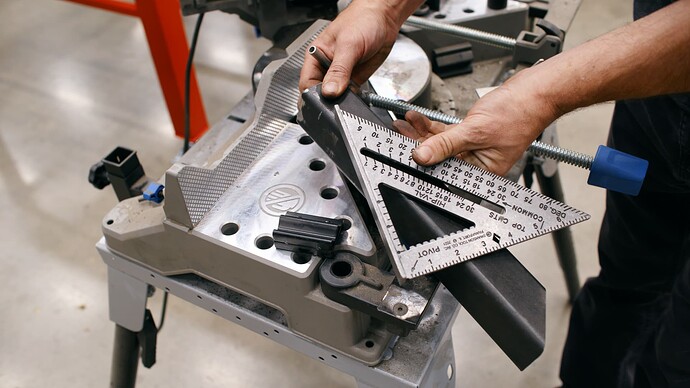

Here’s an example: if I want an opposite miter on tubing, I mark my length, put the Fireball Miter Square on the line, and wrap it around. Done. With a speed square, it’s a two-step process. Mark, roll, re-square. The Fireball Miter Square eliminates that.

It also shines on large radius tubing. A speed square barely hooks the edge and throws off your dimensions. The Fireball Miter Square grabs securely, stays square, and keeps the scale accurate.

Extra Features:

You can wrap perfect lines all the way around tubing.

Carry straight lines across multiple faces without losing reference.

Built-in scales on both sides, like a framing square, so you can reference from either edge.

Flat profile means it sits nicely on surfaces to check miter cuts and layout lines.

Cutouts let you jump over welds while still staying square.

Works for general layout too, hole locations, offsets, or even splitting a 45° into a 22.5°.

It’s surprisingly versatile. You can even use it as a small squaring tool after welding, since it balances itself with a built-in “kickstand.”

Our Final Thoughts:

Between the Fireball miter squares, the speed square, the framing square, and the combination square, you now have four great layout options. Each has strengths, and the Fireball Miter Square brings something new to the table.

They’re available now: 3-pack for $32. I think once you try them, you’ll see how handy they are in the shop.