Hey everyone,

I just made a video where I purchased a Siegmund Table recently and found that their website says “The Strongest, Most Durable Welding Tables Ever Made.” And it got me thinking…is there such thing as the strongest table? What does it take to consider something to be the most durable? Did somebody award this to them?

This claim is on top of a video of them dropping a car on their table, and I couldn’t believe that this is the only thing that makes it the strongest and most durable.

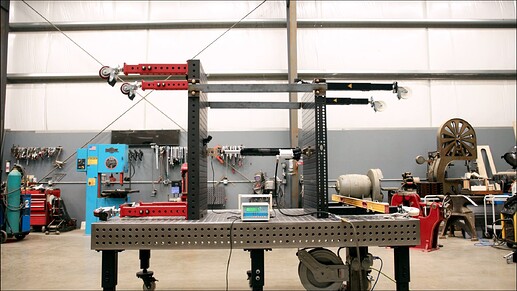

So I put it to the test, and my own Dragon Wagon to compare and see if Siegmund’s claim holds up. Over the course of a series of rigorous tests, I was able to compare the two tables in four key areas: weld spatter durability, overload strength, sidewall strength, and leg attachment robustness. Let’s break down each test and see how the tables fared.

Test 1: Weld Spatter Durability

First up, I wanted to see how the surfaces of both tables handled weld spatter. Anyone who has welded for a while knows how messy it can get, and how some tables suffer from damage after a few poor welds. To simulate this, I did a bit of deliberate bad welding right above both tables, creating plenty of spatter. The goal was to see how each table’s surface reacted to the spatter and if they could clean up without significant damage.

Results:

- Fireball Dragon Wagon: The surface was able to handle the spatter with minimal damage. It’s easy to wipe off, and any marks left behind weren’t too severe, plus the marks were spread fairly thin. But these marks didn’t change the surface itegrity of the table, they were only cosmetic.

- Siegmund Table: The surface more or less performed the same, but had more noticeable cosmetic marks, and the cleanup was little a bit more difficult. I noticed the spatter gathered closer in clusters, rather than spreading out, just something interesting.

Test 2: Overload Strength

The second test focused on seeing how much load both tables could withstand and how they responded to pressure. To do this, I applied a centrally distributed load by pushing against the middle of each table and measuring how much deflection occurred. Then I wanted to see if either table could return to its original flatness after the load was released.

Results:

- Fireball Dragon Wagon: The Fireball table quite well. There was some deflection under load, but the table quickly returned to its original flatness once the pressure was released. The design held up well and only shifted .025" with a couple tons of force applied to it.

- Siegmund Table: The Siegmund table also performed well under load, shifting only .025" under a couple tons of load. And both of these tables went back to their original flatness.

Test 3: Sidewall Strength

Next up was the sidewall strength test. This test was designed to see how the sidewalls of the tables could handle pulling forces. Both tables had their tops chained together and were pulled from the edges to see how much they would bend and if they could return to their flat state afterward. However, there was a hiccup in this test: the Siegmund table’s welding tacks popped during the pull, and the test was halted before I could apply a full load. So, this test ended prematurely for the Siegmund, but here’s how the Fireball performed:

Results:

- Fireball Dragon Wagon: The Fireball’s sidewalls performed excellent under the pull, with minimal deflection and no signs of damage. Before the Siegmund popped, the Dragon Wagon was outperforming its deflection 2 to 1. Even after being pulled significantly, the sidewalls kept their shape and returned to original flatness once I released the load.

Test 4: Leg Attachment Strength

The final test focused on the connection between the legs and the table surface. For this, I chained the legs together and gradually applied increasing pressure to see how much they could take before the connection failed. Then, I switched out the legs and hit them with my 100-pound hammer to see how they handled sudden impacts, simulating running into a divot in a floor, or falling down a stair-step.

Results:

- Fireball Dragon Wagon: The Fireball table’s leg connection system was robust. Even under increasing pressure, the bolts held firm, and the legs remained solidly in place. Then when I hit the leg with the hammer, it took a couple blows before the failure was at the bolt connection- replaceable parts. There was a bit of deformation at the contact points, but nothing that compromised the integrity of the table. The design really impressed me here, showing how replaceable parts can make it easier to maintain the table in the long run.

- Siegmund Table: The Siegmund’s leg connections were more problematic. Under increasing pressure, the connection points began to distort more easily, bending the hardened steel (this test the Siegmund failed compared to the Dragon Wagon leg attachment). Then when I applied the hammer impact, the legs failed in the same spot, bending the hardened steel. It just surprised me that the point of failure was within the table, and not the leg itself.

Final Thoughts:

After conducting all four tests, it’s clear that Siegmund’s claims of having the strongest and most durable welding table, is simply not true. There are way too many categories to have to be the best in to claim that. I don’t think any table could make those claims, honestly.

I was genuinely surprised by how the Siegmund table failed in some of these tests, especially the leg attachment and sidewall strength tests. It’s definitely a solid table, but it didn’t outperform the Dragon Wagon in the areas that matter most for real-world durability.

What do you all think? Have any of you tested the Siegmund table? Let’s talk about it!

Jason