I have absolutely no skin in this game. I’m an IT consultant, and have NEVER been in the same room as a welding device. However, youtube it one hell of a place to hang when you have to wait for a server to finish updating – and that’s how I come to be here.

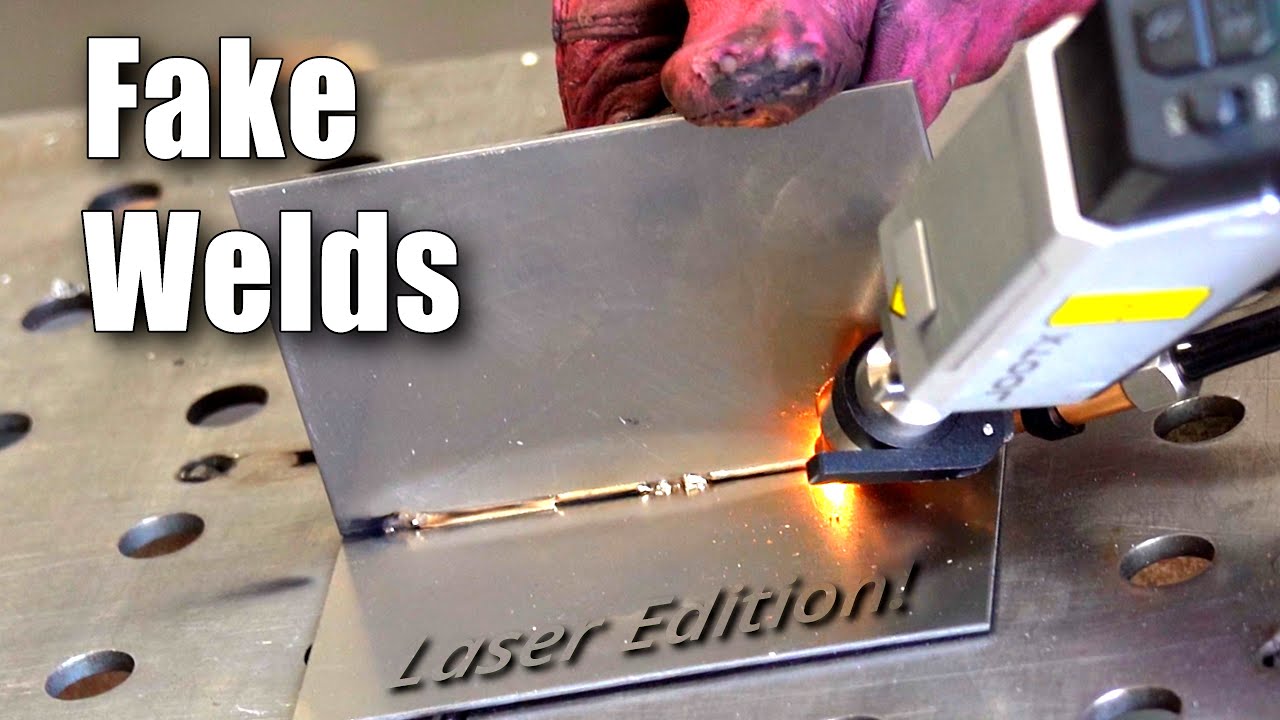

Now for my dilema. I’ve been seeing many videos telling me about the new generation of laser welders. And I don’t trust a single one of them.

Jason:: Can you please do a review? You’re the only person I trust on this!

I’d love to do a review on a laser. I’m intrigued also. From what I see I do think they are the future of welding. It reminds me of plasma cutters when that was becoming popular and adorable in the 90s

1 Like

The Fabrication Series did a good real-world synopsis. He’s a little campy at times, but he does show the real applications and some of the downsides.

My last job in welding was sanitary stainless, and the majority was for pharmaceutical industry. A lot of thin stainless that, after welding, ‘polishers’ blended the joints. Fighting distortion with thin stainless, laser welding would be amazing…until the polishers grind out that ‘too small’ weld while they ‘blend.’ So, even with this laser welder, one pass would have to turn into two or three passes for thin stainless. That being said, the owners don’t pay for experience or give raises. This would be a good choice for them. The laser welder is almost dummy proof. Companies can keep hiring welders for $20-23 /hr or less, now. Hell, they wouldnt need to hire skilled welders.

1 Like