As requested, I’m providing an update. I know… only 9 months later. Keep in mind that I’m doing this in my spare time and when I first posted this last March, I had never welded before and was starting from scratch. So I had to build out my workshop area in my garage with electrical runs, heat, insulation, tooling, storage, compressed air, welding curtain & track, DIY exhaust, etc. and learn to weld.  However now the rubber is finally hitting the road. Also the appearance of welds & grinds are low on my list of priorities with this as I just need it to do the job. Here was my cut pieces for the base:

However now the rubber is finally hitting the road. Also the appearance of welds & grinds are low on my list of priorities with this as I just need it to do the job. Here was my cut pieces for the base:

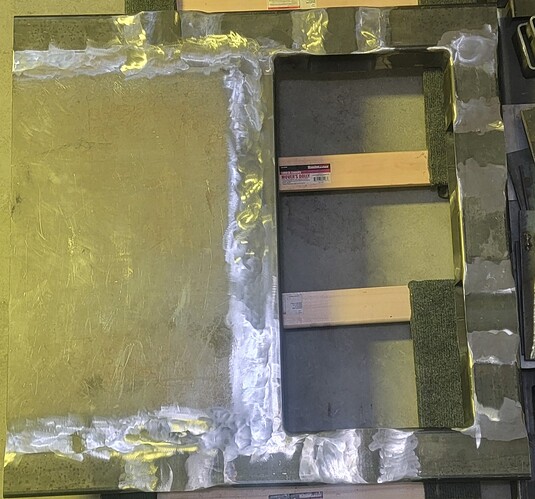

The two 2’ x 3’ dragon wagons weren’t big enough to do it all in one go so I broke it into sections. I did the center part first. Here is the fit up for that:

There still wasn’t enough room to place the fixtures, but it was close. So I got creative, and I used the 4x1x1 fence blocks to step back the 4x1x2 fence blocks by 1". This was kind of handy because it left a 1" tall riser to raise the outside edges off the table. I ran out of those so in a some places I had to use 6x1x2 fence blocks with the pins spaced so the back side could hang off the edge of the table (only 1 pin in a table hole) and kept them from pivoting with 4x1x2 fence blocks next to it at a 90 degree angle.

Then to get each side section, I had to shift the work piece over, one side at a time, hanging off the table. So weld, flip, weld, shift, weld, flip, weld, shift, etc. Here you can see the bottom view with the last side:

Here it is with the bottom 32 holes drilled and the leveling casters test mounted:

And the top with the welds rough ground flat:

Here are the results of how I did with how accurate I got the dimensions, how square, and and how flat (for the top as I don’t care to grind down the bottom welds): Nearly all the way around was about dead on, except one center measurement was less than 1/8" short (still good for my purposes). The diagonal measurements put it within 1/16" of square. I don’t have as good a straight edge as Jason does but I have a quality 4’ level. According to that, taking it across both diagonals, there were only a couple spots that deviated and the worst was only 3/32":

This was across a 40" x 41" footprint. I’m not sure where that ranks with the more experienced folks on here but that seems pretty tight tolerance to me, definitely good enough for my purposes. I know I would not have been able to do that without the fixture table & fixtures, and it seems like it did a really good job at limiting the weld distortion, even in the hands of someone new to fabrication & welding.