In the world of precision welding and fabrication, choosing the right fixture table can dramatically affect accuracy, workflow speed, and repeatability. Two premium choices often compared are Fireball Tool’s heavy duty cast-iron platen platform and Siegmund’s hardened steel System 16 table. While both strive to serve the same core purpose — providing a flat, repeatable work surface with modular fixturing. Today we are going to have an old fashion shootout in the shop between the titans of the industry to test which table is the flattest.

Most fixture tables at first glance look to be a solid machined block of steel with precision located holes that is dead flat. However just like cars its what’s under the hood that really matters and outer looks can be deceiving. Customers need to identify what qualities to look for in a pro grade table.

With that said lets go head to head.

Lets start by comparing the construction on the underside of the tables as the structure and configuration of the ribbing is critical to table rigidity.

The Siegmund system 16 is 12mm (0.47”) thick both in the table top/sides and the ribbing, with one long center rib and 3 intermediate cross ribs. The ribs are affixed to the table top with 3/8-1/2” tack welds. The leg pads are also tied into the ribbing on the center legs, this pushes the leg off of center.

The Fireball standard duty is 1/2” at is thinnest point but averages between 5/8” to 3/4” thick. The table ribbing is 3/4” thick x 5” tall and is capped with a 2” x3/4” strip on the bottom. This creates an I-beam structure that makes the table extremely rigid. This is one of the greatest benefits of casting is you are not confined by what you can make; if you wanted to replicate this shape in plate steel there would be a considerable amount of labor involved. There are 3 long center ribs and 6 intermediate cross ribs. There are also 11 different leg pads integrated on the bottom of the table for different leg configurations.

The Siegmund System 16 features a tool steel top with plate steel side walls and the entire table has had plasma nitride coating applied. The plasma nitride process produces significant heat, we will see if that is a factor in our flatness test

The Fireball Standard Duty features cast iron top and sides with our proprietary Dragon Scale coating.

Now that we have established how both tables are built and differences in design philosophy. Lets take both tables to the 5’x10’ Starret granite surface plate an put these tables to the test with our CMM (Coordinate Measuring Machine).

Up first is the Siegmund System 16.

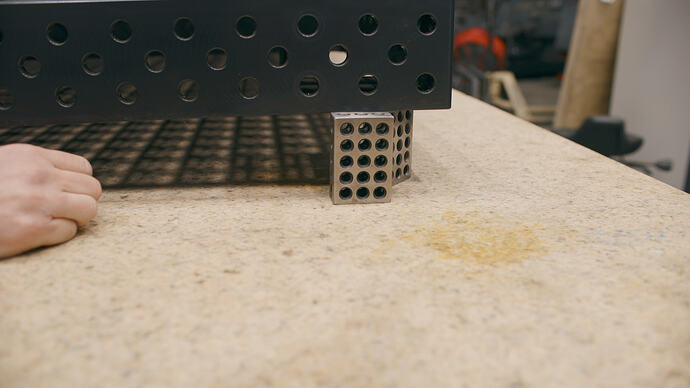

For all of out tests we are placing the tables on the surface plate supported by 123 blocks under the 6 leg locations, the blocks are set on the 3” side.

Siegmund advertises a +/- .019” or .038 total deviation in flatness for all of their tables. After running our tests with the CMM we collected the following data. We have a deviation table and a heat map of the deviation where red shows high spots, blue shows low spots, and green represents the average. The measurement limits are set to +/- .020 or .040 total deviation.

Total deviation on the Siegmund measured .034 or +/-.017, just barely inside their tolerance range but the did make it, notice the heat map shows high edges and a low center and take into consideration how that would affect layout of a weldment. Overall the table does not meet the standard for aerospace fabrication that is +/-.002 over 2ft or +/-.008 over 8ft.

Next we will load up the Fireball Standard Duty.

After completing the same round of tests here are the results for the Fireball.

WOW! what a difference. The fireball measured .011 total deviation or +/-.005, almost 4x as flat as Siegmund and this is over a surface almost 20% larger. This is a very definitive result.

Since we have the tables on the surface plate we are also going to test table sag and flex.

With these tables being on wheels they are often moved around, the casters will follow the concrete bellow them. This makes table sag an important factor to consider because everyone knows that floors are never flat so the table will follow the floor if not rigid enough and when you clamp your parts down they will follow the same contour. If you have a saggy table you will have to re-level after every move if you want to maintain flatness.

To test sag we have removed the center support blocks and removed one corner block.

First up, the Siegmund, and the results could not be clearer. Over an inch of natural sag.

The 123 block on the 2” side will not slide under the table and the deflection is clearly visible in the table top.

Lets add some flex to this situation and see if we can make it worse, both Jason and I hopped up on the table. I am standing on the back corner for 220lbs of counterbalance and Jason is producing the flex load of 170lbs. The results are even worse for the Siegmund.

We are able to add almost another 1 1/2 inches for a total of 2 1/2 inches of flex. This table is about a rigid as a wet noodle.

Lets see how the Fireball Standard Duty fairs in the sag test in comparison.

This test really shows the difference that table construction makes, only approx. .020 of sag and as the flex test will show it there is no additional flex past the sag point.

Even with Jason jumping on the other side the table starts to teeter totter before it flexes anymore.

We think the results of these tests speak for themselves. There is clear difference between the two table platforms when it comes to both rigidity and flatness. One table is built with no compromises to performance and one table is built to a price point and it shows. Keep in mind this is only our Standard Duty table line; we have heavy duty and our super heavy duty line of tables to explore in the future. So stay tuned for more testing in the future, and we will see you guys next time.